What Is a Truck-Mounted Forklift With One-Side Offloading?

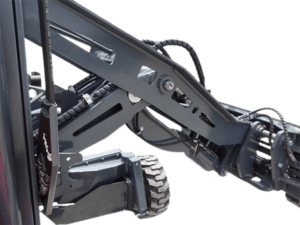

A truck-mounted forklift (often referred to as a piggyback forklift) with one-side offloading (Moffett calls it”pantograh” and Loadmac calls it “iSR [Integrated Second Reach]) is a specialized lifting device integrated with a truck chassis to offload materials from one side. By enabling operators to load and unload goods from one optimized side, especially when employing goloadmac strategies, it eliminates the need for repositioning the vehicle, reducing turnaround time and improving safety by keeping both operator and load within a controlled zone. For further insights, truck mounted forklift secrets provides more detailed guidance.

This system relies on precision-engineered sliding mechanisms and pivot points paired with hydraulic systems and robust reinforcements. In many advanced applications, a piggyback forklift design enhances load distribution and stability. It extends the forklift arm laterally in a controlled, single-axis motion that isolates external influences such as wind or uneven terrain. Additionally, innovations such as GoLoadmac contribute to smoother operation in industries like construction, roofing, and building supply, ultimately benefiting from faster cycles – sometimes reducing unloading time by as much as 20% – while lowering fuel consumption and maintenance costs through reduced equipment needs.

One Side Offloading

Key Benefits of One-Side Offloading Forklifts

Loadmac forklifts standard one-side offloading is built for efficiency. They save time, cut labor costs, and make every delivery safer. By loading and unloading from one side, the driver never has to reposition the truck—so jobs move faster and with less hassle. That also means fewer blind spots and less exposure to traffic, which keeps both the operator and materials safer.

These machines are engineered for control. Precision hydraulics and balanced design reduce wear on the forklift and its cargo. In lumber, concrete, or construction work, that stability pays off—fewer load shifts, less downtime, and longer equipment life. With up to 20% faster unload times and fewer moving parts to maintain, operators spend more time working and less time wrenching.

Industries That Benefit Most

Anywhere materials need to move quickly and safely, one-side offloading forklifts shine. Construction crews use them to place block, brick, and lumber right where they’re needed without moving the truck. Roofing suppliers love the reach. Building supply yards cut load times dramatically.

Lumberyards value how cleanly they handle long or uneven cargo. Manufacturers rely on their consistency for just-in-time production. And logistics operators appreciate the shorter turnaround at docks and yards—every minute saved adds up to real money.

Loadmac Forklifts Advantages for One-Side Offloading

Loadmac forklifts are built with purpose. The lighter chassis and stronger frame improve maneuverability without sacrificing durability. Its hydraulic system is tuned for smooth, steady motion—no jerky lifts or hard stops that can damage a load.

Inside the cab, everything’s designed around the operator. The controls are intuitive, the visibility is excellent, and onboard diagnostics monitor load balance in real time. Compared to traditional systems, Loadmac models have been shown to cut operating costs by up to 15%. They’re also tougher and more dependable than Moffett, thanks to better materials and simpler maintenance.

Performance and Durability: Loadmac vs. Moffett

One-Side Offloading

The Loadmac forklift system uses fully integrated hydraulics and smart sensors for a smoother, faster offload. Moffett units, by comparison, rely more on older mechanical designs—heavier, slower, and less refined.

Loadmac Forklift Y Style Pantograph

Durability and Maintenance

Loadmac forklifts use corrosion-resistant materials and modular construction, making maintenance simple and downtime rare. Moffett’s heavier frame and complex design can mean more repairs and higher upkeep costs.

Ease of Operation

Operators consistently rate Loadmac higher for comfort and ease of use. Digital diagnostics and an ergonomic cab shorten the learning curve and reduce fatigue. Moffett machines often need longer training and show higher error rates over long shifts.

Ownership Value

Lower fuel use, fewer breakdowns, and nationwide support make Loadmac a clear win for long-term cost of ownership. The U.S. dealer network provides reliable service and fast parts delivery—something Moffett owners often struggle to match.

Essential Features of Loadmac Truck-Mounted Forklifts

Lifting Capacity and Reach

The Loadmac 855 Super Reach handles 3–7 tons and extends up to 15% farther than comparable models—perfect for tight job sites.

Safety Systems

Advanced sensors constantly monitor load position and hydraulic pressure. Automatic brakes, reinforced cabins, and onboard diagnostics keep operators compliant with FMCSA and ITSDF standards.

Adaptability

From construction to logistics, Loadmac forklifts adapt easily with options like extended forks, clamps, and custom cabs.

| Feature | Specification | Benefit | Industry Use |

|---|---|---|---|

| Lifting Capacity | 3–7 tons | Handles heavy loads with ease | Construction, Building Supply |

| Reach Extension | 15% greater than competitors | Access tighter spots safely | Urban Delivery, Logistics |

| Safety Sensors | Integrated smart array | Real-time hazard detection | All Industries |

| Hydraulic System | Digital pressure control | Smooth, consistent operation | Manufacturing, Distribution |

| Modular Design | Easy maintenance & upgrades | Lower lifetime cost | Fleet Operations |

Frequently Asked Questions

Q: What does one-side offloading mean?

A: It means you can unload everything from one side—no need to move the truck. The system uses hydraulics and sensors to make it safe and efficient.

Q: How does Loadmac boost efficiency?

A: By combining digital hydraulics, responsive controls, and strong design, Loadmac reduces downtime and speeds up every job.

Q: Why is Loadmac more durable than Moffett?

A: Better materials, modular construction, and smarter engineering. It’s built to last, not just look good on paper.

Q: Which industries benefit most?

A: Construction, roofing, lumber, and logistics—anywhere fast offloading and tight maneuvering matter.

Q: What financing options exist?

A: Loadmac offers lease, finance, and purchase plans with strong resale value and warranty support.

Q: What’s next for Loadmac forklifts?

A: Expect continued innovation—hybrid systems, smart safety tech, and even lighter frames without sacrificing power.

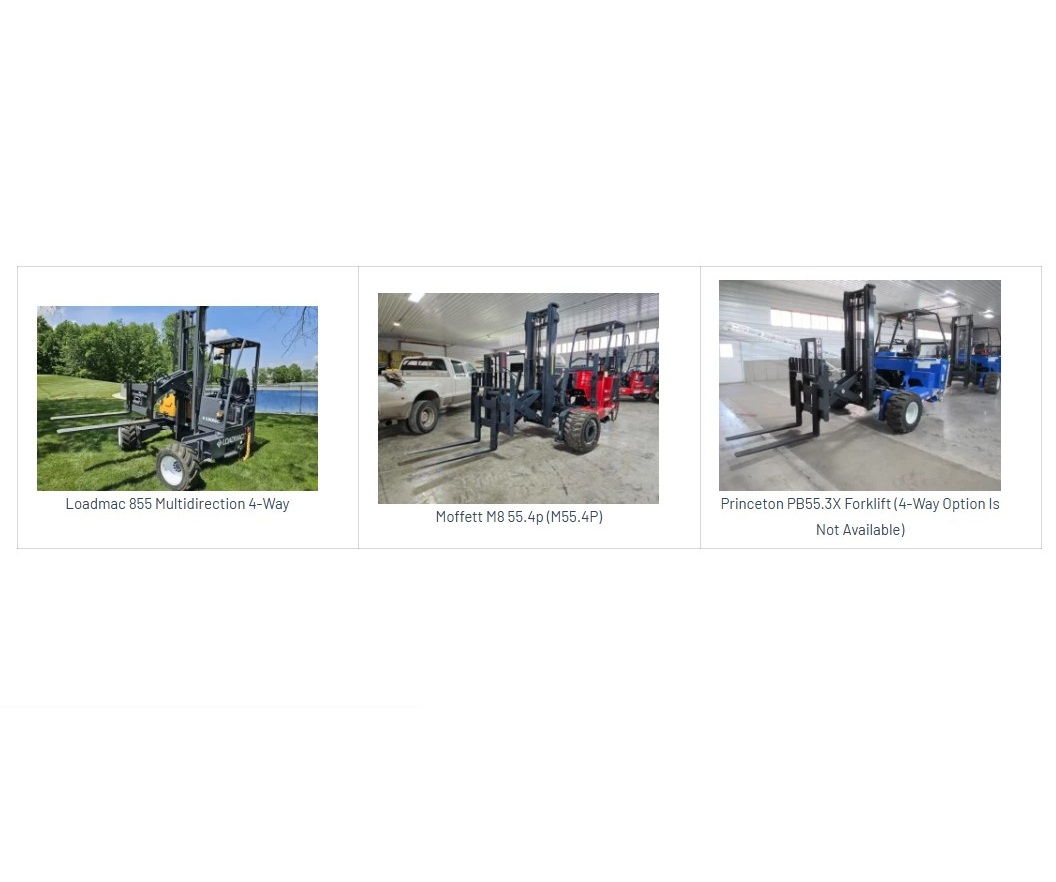

- Battle of Multidirectional Truck Mounted Forklift Giants: Loadmac 855 Super Reach 4-Way vs. Moffett M55.4P

- The Untold Secrets Behind a Piggyback Forklift That Really Works

- Loadmac 855 Super Reach: The Smarter Choice Over Moffett Forklifts and Princeton Piggyback Forklifts

- Unseen Truck Mounted Forklift Benefits for Your Business