Truck Mounted Forklift Advantages Every Buyer Should Know

Truck Mounted Forklift Advantages Every Buyer Should Know: Why Loadmac Stands Out for Performance, Serviceability, and Lower TCO

Understanding why a truck mounted forklift is the first step to recognizing its key advantages. Truck mounted forklifts are purpose-built material-handling units mounted to delivery trucks so crews can load and unload on site without extra equipment. This guide shows how these machines drive real operational gains—greater site flexibility, faster stop times, and less handling damage—for industries like lumber, roofing, landscaping and concrete. You’ll find clear explanations of the core benefits, a close look at what the Loadmac 855 brings to last‑mile workflows, safety and serviceability features that cut downtime, head‑to‑head points of comparison with Moffett and Princeton units, lifecycle cost considerations, and dealer and leasing opportunities. The content is organized around practical buyer questions—payload recovery, one‑side offloading, hill capability, maintenance load and resale outlook—paired with engineering comparisons and deployment advice. Early sections cover fundamentals and common jobsite workflows; later sections include concise comparison tables and dealer-focused guidance to help procurement decisions.

What Are the Core Benefits of a Truck Mounted Forklift for Buyers?

Truck mounted forklifts bring the lift to the jobsite: they combine truck mobility with lifting capability so deliveries go straight from truck bed to placement. Built with an integrated mount, hydraulic lift and steering module, these units let operators offload pallets and multi‑directional loads without waiting on a yard forklift—speeding deliveries and cutting manual handling. For buyers the benefits are concrete: fewer crew per stop, more stops per shift, and reduced product damage from double‑handling.

Forklift Utilization, Cost, and Life Cycle Analysis for Operational Efficiency

A targeted lifecycle study covering utilization, maintenance and cost drivers helps fleets make smarter procurement and allocation choices. The research typically looks at utilization rates, optimal allocation across departments, routine service needs, and total cost of ownership to recommend practical steps that improve uptime and reduce fleet expense.

Those core benefits translate into measurable operational improvements for last‑mile delivery of building materials, landscaping supplies and agricultural freight. In many cases a truck mounted forklift is a strategic capital purchase—not just a convenience—that increases throughput and protects margins.

These units work best where frequent offloads, tight delivery windows or constrained sites make a standalone forklift impractical. The next section explains how mobility and steering systems deliver that jobsite agility.

How Does A Truck Mounted Forklift Improve Versatility and Agility on Job Sites?

Truck mounted forklifts increase on‑site versatility through compact stowage and multidirectional steering that free bed space and enable fast deployment. Many designs use 4‑way or multidirectional steering modules so operators can move easily in tight yards, between racks or on uneven ground—cutting repositioning time compared with manual or truck‑only unloading. That agility is especially valuable for lumber yards, sod farms and other sites with narrow aisles or variable slopes. By reducing per‑stop cycle time, fleets hit more deliveries per route without adding larger trucks or extra labor.

Those mobility gains are a foundation for the efficiency improvements discussed next.

Why Is Efficiency Boosted by Using A Truck Mounted Forklift for On-Site Material Handling?

Efficiency comes from shortening the delivery cycle: direct offloading removes intermediate transfers, cuts labor requirements and lowers damage risk. The integrated lift and steering reduce truck repositioning and double‑handling—the tasks that consume most on‑site minutes—so operators complete more stops per route and reduce per‑delivery labor cost. Put simply, fleets get higher utilization from the same driver hours and can convert saved time into additional revenue or smaller overtime bills.

Those operational gains are reinforced by model‑level features—reach systems, unit weight and serviceability—that compound productivity advantages.

The following section walks through how the Loadmac 855 amplifies these efficiencies.

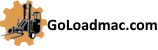

How Does A Loadmac 855 Truck Mounted forklift Deliver Unique Advantages Over Competitors?

The Loadmac 855 truck mounted forklift pairs an engineered reach system with a lightweight chassis and service‑friendly components to improve last‑mile handling. Its Panograph extra reach enables one‑side offloading so drivers spend less time repositioning the truck. Weighing up to 2,200 lbs less than comparable units, the 855 increases payload capacity and lowers fuel use while improving gradability and handling on inclines and rough terrain. Serviceability is simplified with robust engine options and easy‑access service points that reduce maintenance complexity and downtime. Together, these features make the 855 a high‑performance choice with a lower total cost of ownership for owner‑operators, fleets and dealers who prioritize uptime and payload economics.

Below is a concise EAV comparison that shows how the Loadmac 855 attributes compare to typical competitor baselines.

| Model (Entity) | Key Attribute | Value / How It Matters |

|---|---|---|

| Loadmac 855 | Reach system | Panograph extra reach for one‑side offload—faster stops and less truck maneuvering |

| Loadmac 855 | Overall weight | Up to 2,200 lbs lighter in comparable classes, boosting payload and fuel economy |

| Loadmac 855 | Engine / Serviceability | Hatz diesel option with simplified service (no DEF), designed for easier field maintenance |

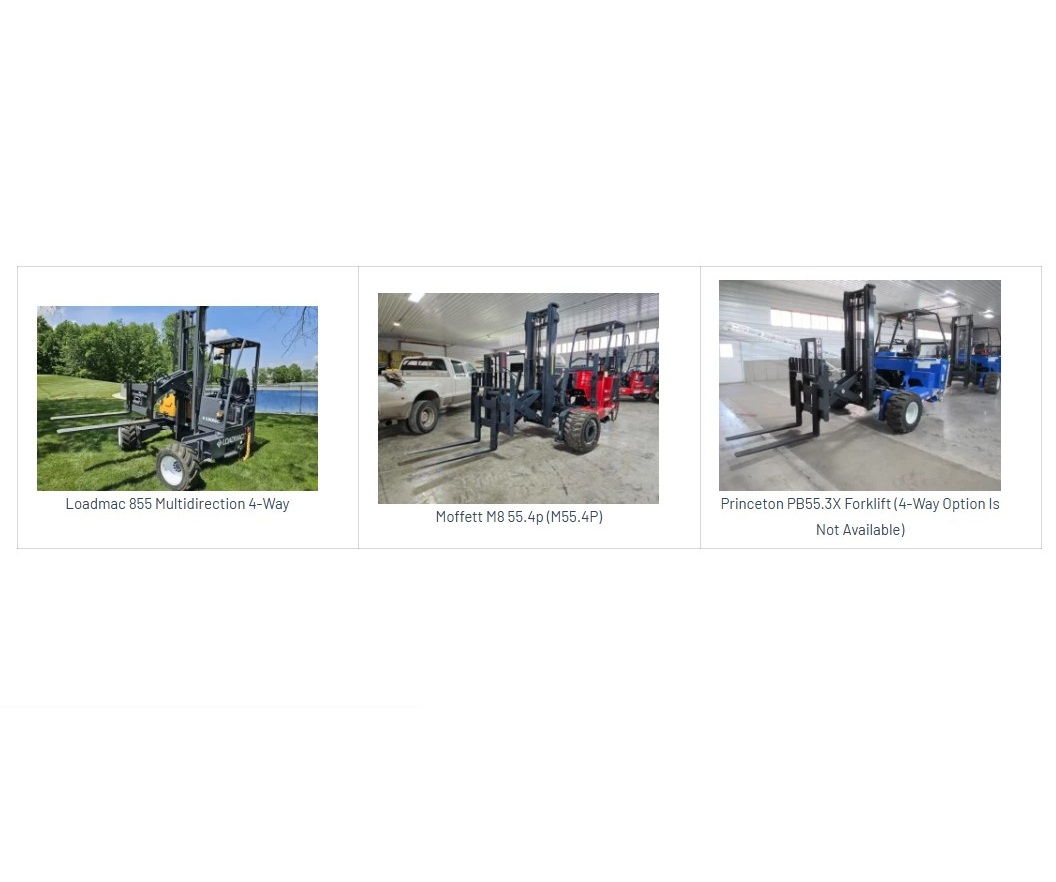

| Moffett (typical model) | Reach system | Alternate mounting and reach design; effective but may need more truck repositioning |

| Moffett (typical model) | Overall weight | Generally heavier chassis compared with lightweight alternatives |

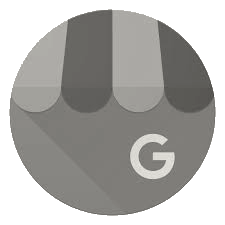

| Princeton (typical model) | Serviceability | Wide parts network; some designs include emissions components that increase service items |

This comparison explains why buyers who focus on payload recovery, stop time and serviceability often favor the Loadmac 855 for demanding last‑mile routes.

Moffett Forklift |  Loadmac 855 Truck Mounted Forklift |

What Is the Impact of One-Side Offloading with Loadmac’s Truck Mounted Forklift Panograph Extra Reach?

The Panograph extra reach lets operators place loads to one side of the truck so they don’t have to reposition for each delivery. Mechanically, the Panograph extends and offsets the load path so pallets are placed without swinging the truck or carrying out multi‑point maneuvers. Operationally that means fewer truck moves, lower fuel use per route and reduced risk of collisions or site damage. For contractors and distribution fleets, minutes saved at each stop add up across a route—raising labor productivity and enabling tighter delivery windows.

Those time savings work together with the 855’s lower unit weight to improve payload economics, described next.

How Does Loadmac’s Lightweight Design Enhance Payload and Fuel Efficiency?

Lighter mounted forklifts free up truck payload and cut fuel use by reducing deadweight on the chassis. The Loadmac 855’s lower weight lets carriers load more material within legal limits or reduce trips—directly improving revenue per route. Reduced weight also improves gradability on slopes and responsiveness on rough ground, helping drivers maintain pace and reducing strain on drivetrains. Combined with the Panograph reach, these design advantages increase per‑stop revenue potential and lower operating costs across busy delivery networks.

With those performance differences established, the next section covers the safety and serviceability features that keep units working in real operations.

What Safety and Serviceability Features Make Loadmac Forklifts Stand Out?

Loadmac focuses on operator safety and easy maintenance through design choices like ground‑level mounting and service access that reduce downtime and lower injury risk. Ground‑level mounting cuts the need to climb into truck beds—reducing fall and strain hazards—and aligns with ergonomic best practices. Serviceability features such as accessible inspection points and durable engine options shorten routine maintenance windows and reduce the chance of extended outages. Together, these design choices help fleets preserve uptime and maintain predictable operating schedules.

- Ground‑level mounting reduces fall risk and makes routine checks faster.

- Simplified service access lowers labor hours for routine maintenance.

- Durable engine options reduce service events tied to emissions treatment systems.

- Design for parts accessibility shortens repair time and speeds returns to service.

Taken together, these attributes create a maintenance and safety profile that protects operators and maximizes unit availability; the following subsection explains ground‑level mounting in more detail.

How Does Ground-Level Mounting Improve Operator Safety and Comfort?

Ground‑level mounting places key controls and service points within reach so operators can do pre‑shift inspections, start‑up and routine checks without climbing onto the truck bed. The mounting secures the forklift at a safe working height and integrates accessible levers and controls that reduce awkward postures and repeated climbs—common sources of fatigue and injury. For fleets with frequent stops or challenging weather, fewer climbs lower slip‑and‑fall exposure and increase inspection compliance, improving both safety outcomes and equipment reliability. These operator improvements also help meet workplace safety recommendations.

Better access to service points complements ground‑level mounting by shortening maintenance cycles, as described next.

Why Is Simplified Serviceability Important for Reducing Downtime?

Simplified serviceability reduces time out of service by making filters, fluid points and other routine checks easy to reach and by limiting the complexity of common tasks. Engines without complex emissions add‑ons, accessible hydraulic layouts and modular mounts cut the skill and time required for routine repairs, enabling faster turnarounds at local shops or by in‑house technicians. Less downtime keeps routes on schedule, lowers emergency service costs and makes parts forecasting more predictable for dealers. Designing for easier maintenance turns uptime into reliable delivery capacity and steadier operating budgets.

These safety and serviceability advantages set the stage for direct brand comparisons in the next section.

How Do Loadmac Forklifts Compare to Moffett and Princeton Models?

When comparing Loadmac, Moffett, and Princeton forklifts, focus on decisive buyer factors: reach capability, weight and payload impact, serviceability, customization, and availability. Map those engineering attributes to operational results—minutes saved per stop, payload recovered from lighter weight, and maintenance complexity’s effect on downtime. Each brand brings strengths: some competitors offer broad dealer networks and strong field service, while Loadmac emphasizes Panograph reach, lighter units and simplified service designs. The right choice depends on route profiles, load mix and a buyer’s maintenance capacity.

| Brand / Model | Feature | Customer Impact |

|---|---|---|

| Loadmac 855 | Panograph extra reach | Less truck repositioning and faster per‑stop service |

| Loadmac 855 | Reduced overall weight | More payload per trip and better fuel efficiency |

| Loadmac 855 | Hatz diesel, simplified service | Shorter maintenance windows and fewer service items |

| Moffett (typical) | Conventional mounting/reach | Reliable operation; may require additional truck maneuvers |

| Princeton (typical) | Broad model line | High customization for special uses but can increase lead time |

Use this mapping to match brand strengths to your operational priorities; the next subsection covers customization and availability differences.

What Are the Key Differences Between Loadmac, Moffett, and Princeton Forklifts?

Truck mounted forklift key differences show up in reach mechanisms, unit weight and service architecture. Loadmac highlights the Panograph reach and a lightweight chassis; Moffett is known for proven piggyback systems and broad availability; Princeton offers many mounting and steering choices for specialized needs. Service ecosystems also vary: some competitors rely on large dealer networks for parts and warranty support, while Loadmac reduces field service needs through simpler mechanical systems. Buyers should rank priorities—speed per stop, payload recovery, parts access—and weigh trade‑offs accordingly.

Those trade‑offs affect procurement timelines and customization choices, which determine which brand best fits a buyer’s operational tempo.

Which Forklift Brand Offers Better Customization and Immediate Availability?

Customization and immediate availability depend on manufacturer and dealer networks. Some brands offer wide factory options for masts, fork attachments and mounts; others keep stock units for quick deployment. Loadmac positions itself with configurable options plus strong availability, offering setups for building materials, roofing, sod and block handling. If you need fast fulfillment or specific mast/fork arrangements, check lead times and dealer readiness—immediate availability reduces project delays and rental costs. Balance customization needs against deployment urgency when choosing a supplier.

Next, we cover how these choices influence total cost of ownership over typical ownership horizons.

What Is the Total Cost of Ownership Advantage with Loadmac Forklifts?

Total cost of ownership (TCO) includes purchase price, integration, fuel, maintenance, downtime and resale value. Loadmac’s focuses—lighter weight, simplified serviceability and reach efficiency—address several of those cost centers at once by increasing payload, lowering fuel use and shortening maintenance time. Over a typical ownership cycle those operational gains can reduce per‑delivery expense and improve net revenue per route. Buyers should quantify utilization, route profiles and maintenance capacity with conservative assumptions for service frequency and fuel to model TCO differences accurately.

The following EAV‑style TCO table summarizes likely 5‑year cost/benefit effects for typical ownership considerations, emphasizing qualitative outcomes rather than specific price estimates.

| Entity (Model/Factor) | Attribute | 5-Year Cost / Benefit |

|---|---|---|

| Loadmac 855 | Maintenance burden | Lower—simplified service points and engine choices cut labor hours |

| Loadmac 855 | Fuel & payload | Improved fuel efficiency and higher payload revenue thanks to reduced unit weight |

| Loadmac 855 | Downtime | Reduced—easier field repairs and better parts accessibility speed returns to service |

| Competitor typical | Maintenance burden | Potentially higher if emissions systems or cramped service points increase shop time |

| Competitor typical | Fuel & payload | Neutral to higher operating fuel costs where unit weight is greater |

This qualitative view helps procurement teams estimate lifecycle savings and prioritize the features that most affect their cost models.

How Does Loadmac Reduce Maintenance and Operating Costs Over Time?

Loadmac reduces maintenance costs by limiting service complexity and making routine tasks faster via accessible service points and durable component choices. Engine options without added emissions treatment components mean fewer specialized consumables and service events; the mechanical layout favors field‑replaceable parts. Fewer maintenance hours reduce labor expense, and faster returns to service lower the need for temporary replacements or rentals. Together, these factors stabilize fleet availability and make maintenance budgets more predictable.

Why Is Loadmac’s Fuel Efficiency a Critical Factor for Buyers?

Fuel efficiency directly affects per‑delivery cost—lighter mounted forklifts reduce rolling resistance and lower the load on the truck engine. By recovering payload capacity through reduced forklift weight, fleets can carry more revenue‑bearing material per trip or cut the number of required trips—both reduce fuel spend. Across large fleets or high‑mileage routes those savings compound and can improve environmental performance. Buyers should model route distances and typical load factors to estimate annual fuel savings tied to lighter mounted units.

How Can Dealers and Leasing Companies Benefit from Partnering with GoLoadmac.com?

Dealers and leasing firms that partner with GoLoadmac.com can add Loadmac’s engineering advantages to their portfolios for customers such as lumberyards, roofers, sod growers and concrete distributors. Partnership opportunities include new unit sales to owner‑operators and fleets, recurring parts and service revenue, and tailored configurations to meet regional needs. GoLoadmac.com positions Loadmac as a practical alternative to legacy piggyback options and supports partners with product knowledge and North American distribution capability. For dealers considering new lines, Loadmac’s combination of availability, customization and TCO advantages makes a strong commercial case.

- Revenue from new unit sales to regional fleets and independent contractors.

- Recurring parts and service income from scheduled maintenance and field repairs.

- Leasing and rental revenue where short‑term capacity is needed during peak seasons.

Those revenue streams, backed by marketing and technical support, form a practical partner proposition; the subsection below explains onboarding and support in operational terms.

How Does GoLoadmac.com Support Dealer Onboarding and Sales Success?

GoLoadmac.com supports dealers with product training, technical documentation, parts support and lead‑generation tools to speed time‑to‑sale and ensure service readiness. Onboarding typically includes sales training materials, spec sheets for procurement and guidance on matching Loadmac configurations to common use cases like roofing and landscaping. GoLoadmac.com also helps with fulfillment planning and parts availability so dealers can hold the right inventory and respond quickly to service requests. This blend of product support and channel enablement helps dealers turn Loadmac’s product advantages into repeatable, profitable business.

- Battle of Multidirectional Truck Mounted Forklift Giants: Loadmac 855 Super Reach 4-Way vs. Moffett M55.4P

- The Untold Secrets Behind a Piggyback Forklift That Really Works

- Loadmac 855 Super Reach: The Smarter Choice Over Moffett Forklifts and Princeton Piggyback Forklifts

- Unseen Truck Mounted Forklift Benefits for Your Business