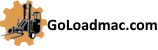

Loadmac Forklifts: The Smart Choice for U.S. Jobsites Compared To Other Truck Mounted Forklift Brands

Among truck mounted forklift brands, Loadmac truck mounted forklifts are changing how contractors and distributors move materials across the U.S. This article compares Loadmac with established manufacturers such as Moffett, Princeton, Donkey, Palfinger, Manitou, Prowler, and Navigator, and explains how different design philosophies affect real-world performance. See how Loadmac’s targeted engineering improves last-mile efficiency and safety—and why many fleets choose it for routine last-mile material-handling work.

Last‑mile logistics are evolving fast — purpose‑built solutions like Loadmac are right at the center of that shift with truck mounted forklift manufacturers.

Truck mounted forklift manufacturers design portable forklifts that mount to delivery trucks and trailers, allowing crews to unload materials directly at the jobsite without additional handling equipment. — Jason Pence

Key Points

- Loadmac’s Focus on Practical Benefits: Loadmac truck mounted forklifts are designed with real-world work in mind, offering faster offloads, lighter footprint, and nimble handling that make last-mile deliveries more efficient.

- Enhanced Offloading with Loadmac 855 Super Reach: The Loadmac 855 Super Reach is optimized for one-side offloading, reducing truck repositioning, cutting downtime, and speeding up delivery while lowering operational risks.

- Lightweight Design Boosts Payload and Fuel Economy: Loadmac’s lighter construction allows for more material per trip and less fuel consumption, saving money and increasing overall efficiency.

- How Loadmac Stands Out in the Market: Compared to major brands like Moffett and Princeton, Loadmac offers a balance of capability and cost, focusing on practical features for everyday routine material handling.

- Industries That Benefit from Loadmac Forklifts: Loadmac forklifts are perfect for lumberyards, sod farms, and building material delivery, offering quick, precise offloads and enhancing safety on site.

New Technologies and Smarter Solutions for Last‑Mile Logistics

Technology is rewriting the last‑mile playbook. As e‑commerce grows, delivery windows tighten, competition intensifies, and teams must do more with less. This review synthesizes 72 papers from 39 publications (2015–2023) to show how technology and new methods are being applied to improve delivery and fulfillment.

A Way of Optimization of Last-Mile Logistics Operations.

A Knowledge-Driven Literature review, MA Aslam, 2025

What Makes Loadmac Stand Out Against Other Truck Mounted Forklift Brands in the USA?

Loadmac truck mounted forklifts focus on practical gains: faster one‑side offloads, a lighter footprint that preserves payload and fuel, and nimble handling for tight jobsites. Engineered for real‑world work—quicker unloads, fewer truck moves, and safer material placement—they make a strong choice for last‑mile delivery of building supplies and other bulky freight.

How Does the Loadmac 855 Super Reach Enhance One-Side Offloading Efficiency?

The Loadmac 855 Super Reach model is tuned for one‑side offloading: it cuts the need to reposition the truck, shortens downtime at each stop, and lets operators set loads exactly where they belong. That combination speeds deliveries and reduces the risk tied to extra truck maneuvers.

Why Is Loadmac’s Lightweight Design Beneficial for Payload and Fuel Efficiency?

Loadmac’s lighter construction translates into more usable payload and improved fuel economy. You can carry more material per trip without exceeding vehicle limits, and the lower weight reduces fuel burn—so over time the machines save money while leaving more of the truck’s capacity available for freight.

Manufacturer Landscape and Design Philosophy

Several established truck mounted forklift brands compete in the U.S. truck mounted forklift market, each bringing a different design philosophy to how their machines are built and used. While specifications such as lift capacity and engine size are often emphasized, the more meaningful differences show up in how manufacturers prioritize weight, reach, stability, and day-to-day usability.

Some manufacturers focus on building heavier, high-capacity machines intended to cover the widest range of applications. Others emphasize rugged construction, accepting additional weight and complexity as a tradeoff. These approaches can be effective in certain scenarios, but they often introduce limitations in maneuverability, axle loading, and efficiency on real jobsites.

Loadmac’s approach is intentional and practical. Rather than optimizing for edge-case specifications, Loadmac designs truck mounted forklifts around how delivery fleets actually operate—frequent unloading, uneven terrain, confined spaces, and strict transport constraints. This focus on real-world performance places Loadmac in a distinct position among truck mounted forklift manufacturers in the USA.

How Does Loadmac Compare To Other Truck Mounted Forklift Brands?

The market features a range of prominent truck mounted forklift brands, each with unique strengths. Key players include:

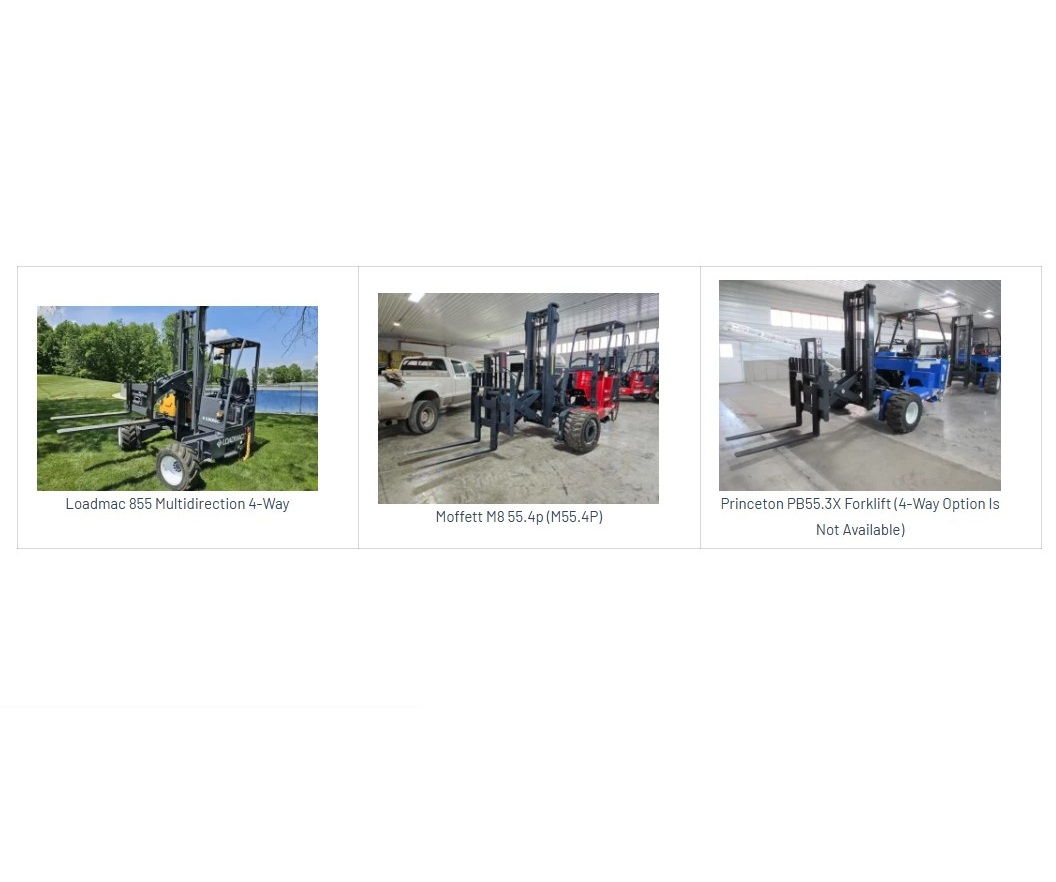

- Moffett

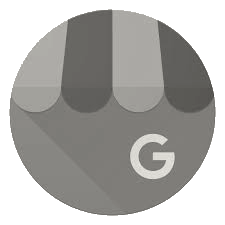

- Princeton

- Palfinger

- Manitou

- Loadmac

- Donkey

- Prowler

- Navigator

While Loadmac carves out its niche amongst other truck mounted forklift brands by focusing on practical gains and cost-effectiveness, the truck-mounted forklift market is rich with established and innovative players, each offering unique advantages. Truck Mounted Forklift brands like Moffett and Princeton have long been industry mainstays, known for their robust designs and wide range of models catering to diverse applications. Moffett, often synonymous with truck-mounted forklifts, offers powerful machines like the M8, recognized for their durability and high lifting capacities. Princeton, another prominent name, provides versatile solutions, including their popular PB series, often favored for their maneuverability and specialized attachments.

Beyond these familiar names, other truck mounted forklift manufacturers contribute significantly to the market. Palfinger, a global leader in lifting solutions, offers truck-mounted forklifts that often integrate seamlessly with their broader range of crane and lifting equipment, providing comprehensive material handling systems. Manitou, with its extensive background in industrial and agricultural equipment, brings a reputation for reliability and advanced engineering to its truck-mounted forklift offerings, often emphasizing operator comfort and efficiency.

Emerging or specialized truck mounted forklift brands like Donkey and Prowler also play crucial roles. Donkey forklifts are often highlighted for their lightweight design, maximizing truck payload and fuel efficiency, making them ideal for specific delivery needs where every pound counts. Prowler, on the other hand, might appeal to users looking for rugged, no-nonsense machines built for demanding environments.

In this competitive landscape, Loadmac distinguishes itself amongst truck mounted forklift manufacturers by prioritizing a balance of capability and cost. Its models, such as the 855 Super Reach, are engineered for real-world efficiency, focusing on features like faster one-side offloads, a lighter footprint, and nimble handling. This targeted engineering allows Loadmac to offer a compelling alternative, providing high performance for routine material-handling work without the premium price tag sometimes associated with other truck mounted forklift brands, making it an attractive choice for fleets seeking optimal value and operational efficiency.

Against truck mounted forklift brands like Moffett and Princeton, Loadmac aims for a balance of capability and cost. Their models include practical features that boost everyday performance without the premium price tag sometimes attached to other piggyback forklifts—making Loadmac an efficient option for many fleets.

Comparison of Top Truck Mounted Forklift Brands

This table provides a comparative overview of leading truck-mounted forklift brands, highlighting their key features. Understanding these differences can help you see how Loadmac stands out in the competitive landscape against other truck mounted forklift manufacturers.

| Brand | Known Strengths | Typical Applications | Weight Class | Price Range |

|---|---|---|---|---|

| Moffett | Durability, High Lifting Capacity | Construction, Heavy Materials | Heavy | $$$ |

| Princeton | Maneuverability, Versatile Attachments | Landscaping, General Delivery | Medium | $$$ |

| Palfinger | Integration with Lifting Equipment | Material Handling, Crane Operations | Heavy | $$$ |

| Manitou | Operator Comfort, Reliability | Agricultural, Industrial | Medium | $$$ |

| Loadmac | Lightweight, Cost-Effectiveness | Lumberyards, Building Materials, Sod Farms | Light | $$ |

| Donkey | Lightweight Design, Fuel Efficiency | Specialized Deliveries | Light | $$ |

| Prowler | Rugged Design, Durability | Construction, Demanding Environments | Heavy | $$$ |

| Navigator | Durability, Rugged Design | Demanding Environments, Construction | Heavy | $$ |

In summary, Loadmac distinguishes itself against truck mounted forklift manufacturers with its lightweight design and cost-effectiveness, making it an ideal choice for industries requiring efficient last-mile delivery. By focusing on practical gains, Loadmac offers a competitive edge in performance and value compared to other established truck mounted forklift brands in the market.

What Are the Key Performance Differences Between Loadmac 855 and Moffett M8 55.3P NX?

Compared to other truck mounted forklift manufacturers, the Loadmac 855 is generally lighter and more nimble, which helps in tight or busy delivery locations. While the Moffett M8 may list higher horsepower on paper, the 855 is optimized for last‑mile handling—prioritizing ease of use, quick positioning, and lower operational overhead for routine deliveries.

Moffett M8 55.3P NX Verses Loadmac 855 Super Reach

Why Choose Loadmac Over Princeton Piggyback Forklifts?

Choosing Loadmac over Princeton piggyback forklifts often comes down to total value: similar or better on‑site performance at a more competitive price, plus features that support safety and fuel efficiency. For businesses focused on day‑to‑day productivity, that mix makes Loadmac an attractive choice.

Which Industries Benefit Most from Loadmac Truck Mounted Forklifts?

Loadmac truck mounted forklifts are versatile across several sectors. They’re especially well suited to lumberyards, sod farms, and roofing and building material distributors—any operation that needs fast, accurate offloads and secure handling of heavy or awkward loads.

How Do Loadmac Forklifts Serve Lumberyards and Sod Farms Effectively?

In lumberyards and sod operations, Loadmac forklifts speed unloading and reduce handling damage by placing materials precisely where crews need them. Their compact maneuverability helps operators work around stacks, pallets, and landscape obstacles—so deliveries are quicker and less disruptive to the yard giving Loadmac an advantage against other truck mounted forklift manufacturers.

What Advantages Does Loadmac Offer for Roofing and Building Material Delivery Over Other Truck Mounted Forklift Manufacturers?

For roofing and building material deliveries, Loadmac machines shorten on‑site time and improve safety. Faster offloads mean more stops per day, and safety systems like the ‘Man On The Ground’ feature give crews confidence when working around heavy loads—helping prevent accidents and keep projects moving.

What Innovative Features and Technologies Does Loadmac Offer?

Loadmac forklifts integrate practical technologies designed to improve handling and protect operators. With a focus on maneuverability, precise load placement, and jobsite safety, these features help crews work faster with less risk.

How Does 4-Way Steering Improve Maneuverability in Tight Spaces?

4‑way steering gives Loadmac forklifts true multi‑directional movement, making it easier to navigate tight yards, narrow alleys, and crowded jobsites. That flexibility helps operators position loads more accurately and lowers the chance of costly collisions.

What Is the ‘Man On The Ground’ Safety Feature and How Does It Enhance Operator Safety?

The ‘Man On The Ground’ safety system protects ground personnel during offloads by improving visibility and control when handling loads. It’s a practical safeguard that prioritizes safety without slowing essential delivery tasks.

How Can You Purchase or Partner with Loadmac in the USA?

Getting a Loadmac is straightforward—whether you want to buy or lease. The company offers acquisition options to fit different fleet sizes and budgets, and provides dealer support for service and parts.

What Are the Steps to Buy or Lease a Loadmac Truck Mounted Forklift?

Start by defining your payload needs, truck specs, and budget. Then contact Loadmac or an authorized dealer to review models and financing options. The sales team will guide you through the paperwork and delivery timeline to keep the process smooth.

How Can Dealers Join the Loadmac Dealer Program and Benefit?

Dealers who join the Loadmac program get product training, marketing materials, and sales support to sell and service Loadmac equipment effectively. The program is designed to help partners grow sales while delivering dependable local support to customers.

Frequently Asked Questions

What maintenance is required for Loadmac truck-mounted forklifts?

Regular maintenance for Loadmac truck-mounted forklifts includes routine inspections, fluid checks, and component servicing. Operators should inspect hydraulic systems, brakes, and tires frequently to ensure optimal performance. Following the truck mounted forklift manufacturer’s maintenance schedule is crucial for prolonging the lifespan of the equipment. Additionally, keeping the forklifts clean and free from debris can prevent mechanical issues and enhance safety. Loadmac also provides guidelines and support for maintenance, ensuring that operators can keep their equipment in top condition.

Are Loadmac forklifts suitable for outdoor use?

Yes, Loadmac truck-mounted forklifts are designed for outdoor use, making them ideal for various job sites, including construction and landscaping. Their robust construction and features like 4-way steering enhance maneuverability on uneven terrain. However, operators should consider weather conditions and the specific environment when using these forklifts. Proper training and adherence to safety protocols are essential to ensure safe operation in outdoor settings, especially when handling heavy loads or navigating challenging landscapes.

What is the average lifespan of a Loadmac truck-mounted forklift?

The average lifespan of a Loadmac truck-mounted forklift can vary based on usage, maintenance, and operating conditions. Generally, with proper care and regular maintenance, these forklifts can last anywhere from 10 to 15 years. Factors such as frequency of use, load weight, and environmental conditions can impact longevity. Investing in routine servicing and adhering to operational guidelines can help maximize the lifespan and reliability of the equipment, ensuring it remains a valuable asset for your fleet.

Can Loadmac forklifts be customized for specific applications?

Yes, Loadmac offers customization options to tailor their truck-mounted forklifts for specific applications. Depending on the needs of the business, modifications can include specialized attachments, enhanced safety features, or adjustments to the forklift’s specifications. This flexibility allows operators to optimize performance for unique tasks, such as handling specific materials or navigating particular job site conditions. Consulting with Loadmac representatives can help identify the best customization options to meet operational requirements effectively.

What training is available for operators of Loadmac forklifts?

Loadmac provides comprehensive training programs for operators to ensure safe and efficient use of their forklifts. Training typically covers operational procedures, safety protocols, and maintenance practices. This education is crucial for minimizing accidents and maximizing productivity on job sites. Additionally, Loadmac may offer resources such as manuals, online tutorials, and hands-on training sessions through authorized dealers. Investing in operator training not only enhances safety but also improves overall equipment performance and longevity.

How do Loadmac forklifts contribute to sustainability in logistics?

Loadmac forklifts contribute to sustainability in logistics through their lightweight design and fuel efficiency. By optimizing payload capacity, these forklifts allow for fewer trips, reducing fuel consumption and emissions. Their advanced engineering also minimizes operational waste, promoting a more eco-friendly approach to material handling. Furthermore, Loadmac’s focus on safety and efficiency helps streamline logistics processes, which can lead to reduced resource use and a smaller carbon footprint in the supply chain.

Final Thoughts

Loadmac brands truly stands out among other truck mounted forklift manufacturers by offering an unparalleled blend of lightweight design, cost-effectiveness, and targeted engineering for real-world efficiency. While competitors often focus on raw power or specialized niches, Loadmac prioritizes practical gains like faster one-side offloads and superior fuel economy, delivering high performance for material-handling of capability and cost. Their models include practical features that boost everyday tasks without the premium price tag. This strategic focus makes Loadmac a compelling choice for fleets seeking optimal value and operational efficiency, distinguishing it from other truck mounted forklift manufacturers in the market.

Loadmac truck-mounted forklifts offer significant advantages in last-mile logistics over other truck mounted forklift manufacturers, including enhanced efficiency, safety, and cost-effectiveness. Their innovative design and practical features make them a smart choice for various industries, ensuring reliable material handling without compromising on performance. By choosing Loadmac over other truck mounted forklift manufacturers, you can optimize your operations and improve productivity on job sites. Discover how Loadmac can transform your material handling needs by exploring our range of models today.

About The Author

This comprehensive overview is provided by Jason Pence, AVP of GoLoadmac.com National Distributors. His extensive experience and deep understanding of the truck mounted forklift material handling industry underscore the expert insights and practical advice shared throughout this article, reinforcing the information’s authority and trustworthiness.

- Battle of Multidirectional Truck Mounted Forklift Giants: Loadmac 855 Super Reach 4-Way vs. Moffett M55.4P

- The Untold Secrets Behind a Piggyback Forklift That Really Works

- Loadmac 855 Super Reach: The Smarter Choice Over Moffett Forklifts and Princeton Piggyback Forklifts

- Unseen Truck Mounted Forklift Benefits for Your Business