Loadmac 855 Super Reach: The Smarter Choice Over Moffett Truck Mounted Forklifts and Princeton Piggyback Forklifts

Loadmac 855 Super Reach Truck Mounted Forklifts

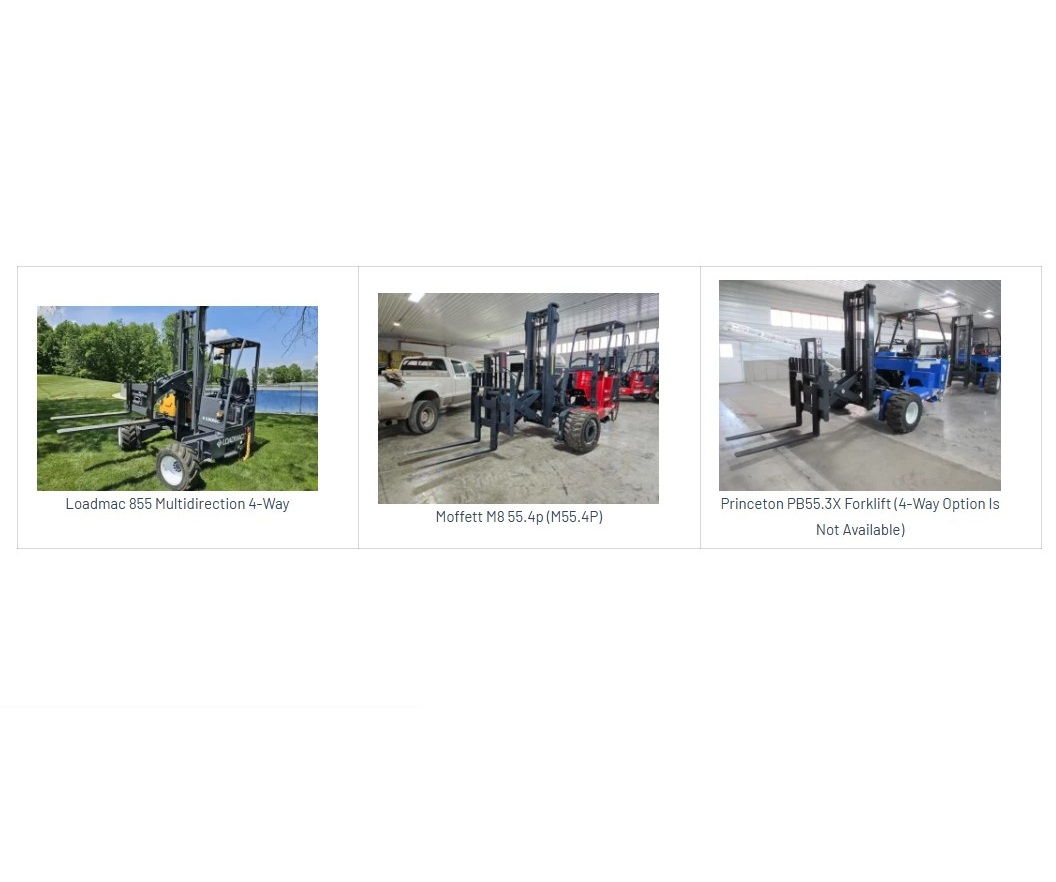

In the world of piggyback forklifts and truck mounted forklifts, most buyers compare Loadmac forklifts directly against Moffett forklifts and Princeton forklifts. On paper, many models show similar lift capacities. In real-world jobsite conditions, however, engineering details make a measurable difference. The Loadmac 855 Super Reach separates itself with standard integrated second reach (iSR), lighter 4-way configurations, tighter maneuverability, and superior climbing performance.

If you are currently running a Moffett M8 55.3P, M55.4P truck mounted forklifts, or a Princeton PB55X, PBX, or PB45.3 STM piggyback forklift, this comparison explains why more fleets are reconsidering what “comparable” really means.

Princeton PB55x Piggyback Forklift |  |

The Defining Advantage: Standard Integrated Second Reach (iSR)

The new Loadmac 855 truck mounted forklift offers one-side offloading and a Y style pantograph design—an ideal alternative to Moffett and Princeton models.

Unlike the Princeton PB55X or Moffett M8 55.3P, the single biggest structural advantage of the Loadmac 855 is its standard engineered panograph reach system, known as integrated second reach (iSR).

- iSR is standard on the 855 — not an optional add-on.

- The panograph is engineered into the frame, not bolted on later.

- Full reach performance is balanced and weight-optimized.

By contrast, pantograph reach on comparable Moffett forklifts, such as the Moffett M8 55.3P or M55.4P, and on Princeton piggyback forklifts, such as the Princeton PB55X, is relatively rare and significantly heavier, especially in 4-way versions. Added reach typically means added mass. Added mass means more axle load, more overhang, and more stress on the host truck.

The Loadmac 855 Super Reach delivers extended placement capability without the weight penalty typically associated with pantograph models.

Weight Matters: Lighter 4-Way Performance

On delivery trucks, weight is not theoretical. It directly affects:

- Rear axle load limits

- Suspension stress

- Legal payload capacity

- Fuel consumption

The Loadmac 855 4-way configuration is lighter than comparable Moffett forklifts and many Princeton forklifts in similar capacity classes. This lighter structure results in:

- Reduced rear axle load on the delivery truck

- Improved departure angle on steep driveways

- Less long-term suspension fatigue

- Cleaner truck integration with less tail swing

When comparing against a Moffett M55.4P or M8 55.3P 4-way or piggyback forklift, the weight difference becomes operationally significant — especially for fleets running shorter flatbeds or operating close to axle limits.

Loadmac Truck Mounted Forklifts: Tighter Turning Radius and Jobsite Agility

The Loadmac 855 Super Reach is not just lighter — it is more agile. Reduced overhang and optimized weight distribution allow for:

- Tighter turning radius

- Less tail swing during maneuvering

- Improved maneuverability in tight residential drops

- Better performance in confined lumberyard lanes

For operators used to heavier Moffett forklifts or larger Princeton PB55X models, the difference in maneuverability is noticeable on first use.

Superior Gradeability and Traction

Climbing performance is one of the most overlooked differences in piggyback forklifts.

The Loadmac 855 offers:

- Better gradeability for steep inclines

- Improved traction due to optimized weight balance

- Lower center of gravity for enhanced stability

- More stable performance at full reach

On uneven terrain, steep gravel drives, or rural construction sites, the combination of lighter weight and better weight distribution provides measurable climbing confidence over heavier pantograph-equipped competitors.

Loadmac Truck Mounted Forklifts

Fixed Mast Design: Stability Over Complexity

Unlike designs where the entire mast structure shifts, the Loadmac 855 utilizes a fixed mast with tilt and side-shift located in the fork carriage. That difference matters.

- Reduced frame flex under load

- Less mass moving during tilt functions

- Smoother hydraulic operation

- More precise fork placement

- Greater stability at full extension

This is especially relevant when comparing to Moffett forklifts or Princeton forklifts where mast movement involves more structural mass. Moving less mass equals more control.

Visibility, Mounting, and Real-World Usability

The Loadmac 855 Super Reach also improves daily usability in ways operators immediately appreciate:

- Lower-profile hood for better forward visibility

- Reduced visual obstruction when backing into tight drops

- Rear ground controls for safer mounting and dismounting

- Wider space between front frame rails for bulky materials

- Reduced transport bounce due to lower center of gravity

- Quieter engine and improved operator comfort

These refinements may not show up in a spec sheet comparison between a Princeton PB45.3 STM and a Loadmac 855, but they directly affect daily fatigue, load placement speed, and overall jobsite efficiency.

Loadmac Truck Mounted Forklifts

Better Power-to-Weight Ratio

Because the 855 platform is lighter while maintaining 5,500 lb lift capacity, it achieves a stronger power-to-weight ratio than many comparable Moffett forklifts and Princeton forklifts.

The result:

- Faster acceleration under load

- Improved cycle times

- Better incline performance

- More responsive hydraulic feel

Over hundreds of deliveries per month, small cycle-time gains compound into meaningful productivity improvements.

Head-to-Head: Where the Loadmac 855 Super Reach Excels Against Moffett M8 55.3P and Princeton PB55X Piggyback Forklift

| Feature | Loadmac 855 Super Reach | Moffett M8 55.3P / M55.4P | PB55X / PBX / PB45.3 STM |

|---|---|---|---|

| Integrated Reach | Standard engineered iSR | Optional, heavier pantograph | Varies by model |

| 4-Way Weight | Lighter configuration | Heavier with pantograph | Generally heavier |

| Turning Radius | Tighter | Wider | Comparable to heavier chassis |

| Gradeability | Superior climbing performance | Good but weight-sensitive | Model dependent |

| Mast Design | Fixed mast, carriage tilt/shift | Mast movement design | Mast movement design |

| Truck Integration | Reduced overhang, cleaner mount | Longer overhang | Varies |

Why Fleets Are Reconsidering Moffett and Princeton Piggyback Forklifts

Many fleets running Moffett forklifts or Princeton forklifts initially focus on brand familiarity. However, when decision-makers evaluate axle load impact, climb performance, maneuverability, and reach weight penalties, the Loadmac 855 Super Reach often presents a more engineered solution.

In piggyback forklifts and truck mounted forklifts, lift capacity alone does not determine performance. Weight distribution, reach integration, mast design, and truck compatibility determine long-term operational efficiency: this is where Loadmac wins.

Wrapped It Up

The Loadmac 855 Super Reach delivers extended reach as a standard feature, lighter 4-way configurations, tighter maneuverability, superior climbing gradeability, and a more stable fixed mast architecture. When compared directly against Moffett forklifts such as the Moffett M8 55.3P and M55.4P, or Princeton forklifts like the PB55X and PB45.3 STM, the engineering advantages become clear.

For fleets that value reach without weight penalties, agility without instability, and durability without excess mass, the Loadmac 855 stands as a refined evolution in truck mounted forklift design.

- Battle of Multidirectional Truck Mounted Forklift Giants: Loadmac 855 Super Reach 4-Way vs. Moffett M55.4P

- The Untold Secrets Behind a Piggyback Forklift That Really Works

- Unseen Truck Mounted Forklift Benefits for Your Business

- Why Smart Businesses Are Switching to Loadmac 855 Over Moffett Forklifts for Better Efficiency and Savings