Moffett Forklifts Versus Loadmac: Why Choose Loadmac?

Moffett forklifts were the first mover, but in this post, we’ll explain why more fleets are taking a serious look at Loadmac. Truck mounted forklifts are central to fast, reliable material delivery—especially for last-mile drops. This guide explains the practical differences between Loadmac and Moffett so you can see where Loadmac often delivers better value in engineering, operating cost, and real-world jobsite performance.

We cover the design advantages of Loadmac over Moffett forklifts, model comparisons, total cost of ownership, and how Loadmac supports specific industries and dealer opportunities at GoLoadmac.com.

Balancing upfront cost, ongoing performance, and lifecycle expense is critical to a smart equipment choice—industry research reinforces that approach.

Forklift Equipment Cost & Selection Factors

When choosing equipment, weigh purchase versus lease or rental and the project’s full lifecycle cost. Key considerations include operating expenses, maintenance needs, uptime and how well the machine matches the job on day one and over time.

Construction equipment management, GC Migliaccio, 2019

What Are Truck Mounted Forklifts and How Do Loadmac and Moffett Forklifts Compare?

Truck-mounted forklifts combine transport and lifting in one unit, so deliveries arrive and unload right at the jobsite. That eliminates the need for separate unloading gear and speeds turnaround. Both Loadmac and Moffett serve this niche, but their engineering approaches differ in ways that matter on the ground.

What Defines Truck-Mounted and Piggyback Forklifts?

Truck-mounted forklifts ride on the back of a truck for transport and immediate use. The label piggyback forklift is often used in the same way, but “piggyback forklift” is actually a trademark of Princeton forklifts. In everyday language, piggyback forklift and truck mounted forklift are interchangeable.

How Do Loadmac and Moffett Forklifts Brands Differ in Market Position and Innovation?

Loadmac focuses on practical engineering improvements that directly affect stability, maneuverability, and payload. Moffett is known for long-standing, proven platforms. If you prefer a familiar, time-tested design, Moffett remains a solid option. If you want a forklift that has been engineered to solve common jobsite frustrations—tight turns, payload limits, stability, and reach—Loadmac often stands out.

In practical terms, there’s very little a Moffett can do that a Loadmac cannot. But there are several things a Loadmac does differently that can make daily work easier and more efficient.

What Engineering Advantages Make Loadmac Forklifts Stand Out?

Lighter Weight, Less Overhang, and Better Stability

One of the biggest practical advantages of Loadmac is its lighter overall weight. A lighter forklift means:

- More legal payload on the truck

- Less strain on the chassis and suspension

- Better fuel efficiency

Loadmac’s design also reduces rear overhang and lowers the center of mass. This improves stability on uneven terrain and during lifting, especially when working on slopes, gravel, or jobsite mud. The result is better gradability and more confident handling on real-world surfaces.

Tighter Turning and Better Jobsite Agility

Loadmac forklifts are designed with tighter turning geometry and a more compact footprint. Combined with optional 4-way steering, this gives operators:

- Tighter turning radius in crowded yards

- Better maneuverability between stacks or pallets

- Less repositioning on narrow streets or job sites

For drivers working in residential developments, urban deliveries, or congested lumberyards, this difference is noticeable from the first day.

Solid Mast Design with End-Mounted Tilt and Side-Shift

Unlike some designs where the entire mast structure moves, Loadmac uses a solid mast with tilt and side-shift at the end of the mast. This offers:

- More precise load control

- Less structural movement during lifting

- Improved stability when placing materials

In practical terms, it helps the operator “set” loads more accurately, especially when placing materials on upper floors or tight drop zones.

Wider Opening Between Front Wheels

Loadmac’s wider space between the front wheels provides:

- Better visibility through the machine

- Easier handling of wider or awkward loads

- Improved load stability during transport

This is particularly useful in lumber, masonry, and building materials applications where pallet sizes vary.

More Power, Less Noise

Loadmac engines typically offer slightly higher horsepower—around 5% more in comparable classes—while running quieter than many competing machines. That combination gives operators:

- Smoother operation under load

- Better performance on inclines

- Reduced operator fatigue over long shifts

How Does Loadmac 855’s Panograph Extra Reach Enhance One-Side Offload?

The Loadmac 855 uses a panograph extra-reach system that makes one-side offloading fast and reliable—perfect for tight urban jobs. Operators can unload without moving the truck, cutting handling time and labor on space-constrained sites. Best of all, this feature is standard on the 855.

How Does Loadmac 855 Compare Directly to Moffett M8 55.4P and Princeton PB55.3x?

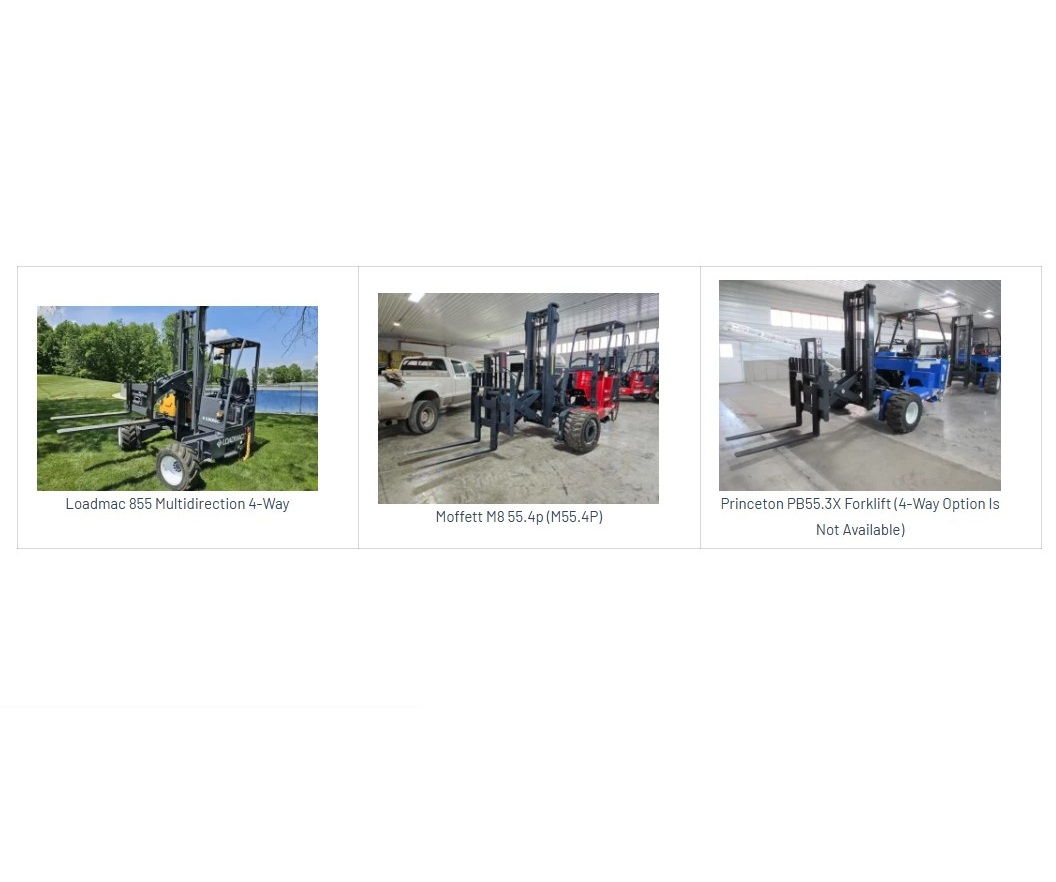

Loadmac 855 Multidirection 4-Way |  Moffett M8 55.4p (M55.4P) |  Princeton PB55.3X Forklift (4-Way Option Is Not Available) |

What Are the Differences in Loadmac and Moffett Forklifts Performance, Power, and Hydraulic Systems?

The Loadmac 855 features a hydraulic setup tuned for smooth, dependable lifting—comparable to the Moffett M8 55.4P and the Princeton PB55.3x. In many real-world uses, differences are incremental.

However, Loadmac adds several practical advantages:

- Lighter weight for higher legal payload

- Lower center of gravity for better stability

- Tighter turning radius

- Standard reach on many models

Princeton is at a disadvantage in this comparison because it does not offer a 5,500-lb capacity 4-way forklift with extra reach in this class.

Which Safety Innovations Does Loadmac Offer That Competitors Don’t?

Loadmac integrates safety into its base design. The lower center of gravity improves stability, while features like the seatbelt interlock ensure operators are properly secured before driving. These design choices reduce tip risk and promote safer operation in everyday use.

What Is the Total Cost of Ownership Advantage of Choosing Loadmac?

How Does Loadmac Improve Fuel Efficiency and Reduce Operational Costs?

Loadmac forklifts are built for efficiency. The lighter construction, quieter engines, and stable design all contribute to:

- Lower fuel consumption

- Reduced tire and component wear

- Less downtime from instability-related damage

Over time, these factors can significantly lower the total cost of ownership.

Truck-Mounted Forklift Ownership Costs

When planning purchases, factor in ownership costs such as maintenance, downtime, and any structural or logistical changes required to integrate new equipment.

Top Reasons to Choose Loadmac Over Moffett Forklifts

- Lighter weight – Improves payload capacity and fuel efficiency.

- Less rear overhang – Better balance and reduced truck strain.

- Lower center of mass – Increased stability and safer handling.

- Better gradability – Stronger performance on slopes and uneven ground.

- Tighter turning radius – Easier maneuvering in tight jobsites.

- Standard extra reach – Faster one-side offloading.

- Solid mast design – More precise load placement.

- Wider front-wheel opening – Better handling of bulky materials.

- Quieter, slightly more powerful engines – Smoother operation and reduced operator fatigue.

Comparative Analysis: Loadmac vs. Moffett Forklifts

| Feature | Loadmac Advantage | Moffett |

|---|---|---|

| Operating Weight | Lighter design improves payload and fuel efficiency | Generally heavier in comparable classes |

| Center of Gravity | Lower center of mass for improved stability | Higher center of mass in many models |

| Turning Radius | Tighter turning for confined spaces | Larger turning radius |

| Reach Capability | Standard panograph reach on key models | Reach options vary by model |

| Mast Design | Solid mast with end-mounted tilt and side-shift | Different mast configurations |

| Engine Performance | Quieter operation with slightly more horsepower | Proven engines, typically louder |

The Verdict

Choosing Loadmac forklifts can deliver real advantages in stability, maneuverability, payload efficiency, and total cost of ownership. For operators who want a machine that feels more balanced, turns tighter, and carries more legal payload, Loadmac is often the practical choice.

Explore the full lineup and find the right fit for your fleet at GoLoadmac.com.

- Battle of Multidirectional Truck Mounted Forklift Giants: Loadmac 855 Super Reach 4-Way vs. Moffett M55.4P

- The Untold Secrets Behind a Piggyback Forklift That Really Works

- Loadmac 855 Super Reach: The Smarter Choice Over Moffett Forklifts and Princeton Piggyback Forklifts

- Unseen Truck Mounted Forklift Benefits for Your Business