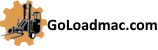

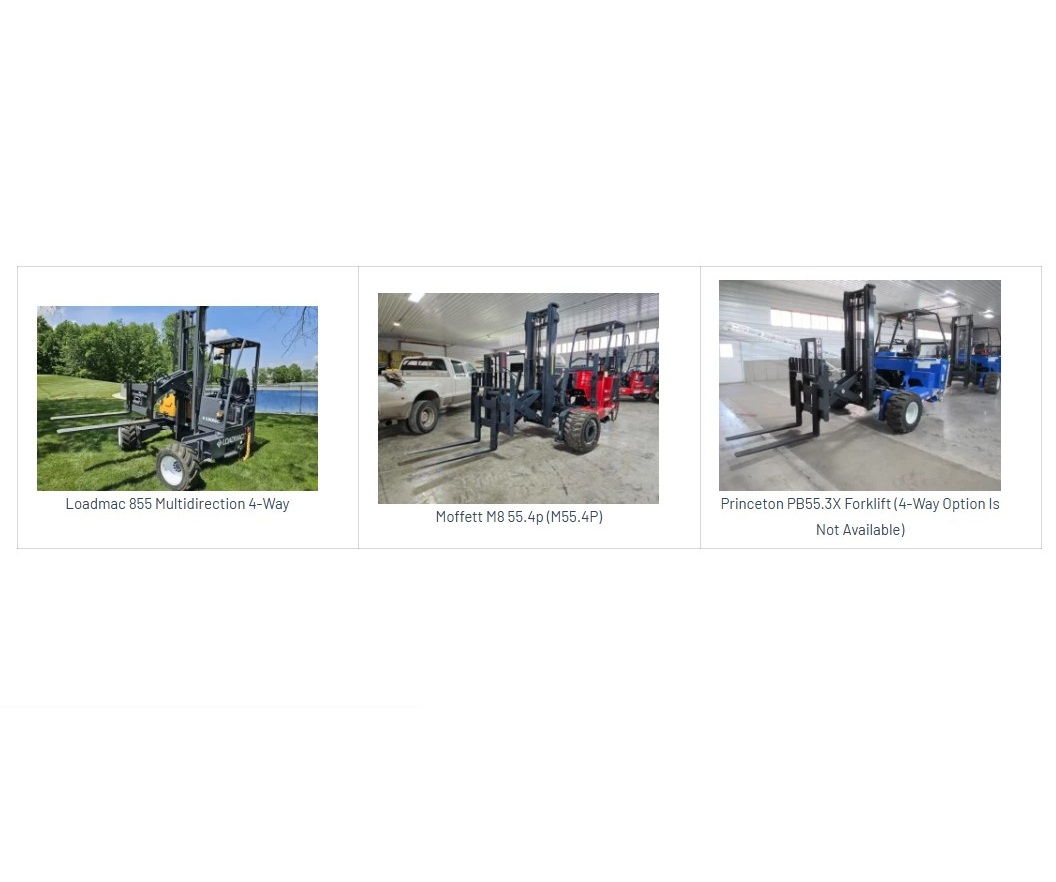

Loadmac 855 vs Moffett forklifts: Moffett M8 55.3, A Practical Truck Mounted Forklift Comparison for Buyers

Moffett truck mounted forklifts, such as the Moffett M8 55.3, are the mainstay of Moffett forklifts’ product line. The competing Loadmac 855 and the goliath Moffett’s units are piggyback style forklifts built to speed last-mile delivery of building materials while cutting on-site handling. Buyers comparing Moffett truck mounted forklifts to Loadmac equipment typically focus on reach, gradability, lift control, and real-world cycle time.

Moffett M8 55.3 | Loadmac 855 |

This guide compares operational performance, safety features, maintenance demands, and total cost of ownership so fleet managers can make informed decisions. If you are cross-shopping Moffett forklifts and Loadmac, the goal is to translate spec-sheet numbers into jobsite outcomes for lumberyards, roofing suppliers, masonry yards, and sod operations. Fewer repositions, fewer steps, and more deliveries per shift than many Moffett truck mounted forklifts workflows allow.

Key performance differences between Loadmac 855 and Moffett truck mounted forklifts Moffett m8 55.3 Model

This section defines the core performance metrics used when comparing Moffett truck mounted forklifts: lift capacity, engine design, curb weight, gradability, and reach. These details determine usable lift for long loads, climbing ability on steep drives, and how often a driver must reposition the truck. Those same factors strongly influence long-term satisfaction with Moffett forklifts.

| Model | Characteristic | Typical Value / Impact |

|---|---|---|

| Loadmac 855 | Panograph extra reach | Allows one-side offloading of long materials and reduces repositioning |

| Loadmac 855 | Engine type | Hatz diesel (DEF-free) simplifies emissions servicing |

| Moffett M8 55.3 | Manufacturer | The Moffett M8 55.3 is built by Hiab and representative of common Moffett forklifts design |

How do lift capacity and engine power compare?

Lift capacity and engine performance determine how a truck-mounted forklift handles full pallets, long bundles, and repeated delivery cycles. Rated capacity is only a starting point. Long loads reduce usable lift at extension, while engine torque and hydraulic flow determine lifting performance under slope and repeated operation. These differences become clear when operators compare Hiab‘s Moffett truck mounted forklift to the Loadmac 855 under identical jobsite conditions.

Many Moffett forklifts use anti-stall hydraulic pump systems that improve feathering control but reduce available hydraulic horsepower. In real-world use, this can limit hill-climbing speed and lifting momentum compared to Loadmac, particularly when carrying heavy pallets up steep residential or commercial driveways common in Moffett truck mounted forklifts delivery routes.

What advantages does the Loadmac 855 offer in gradability and maneuverability Over the Moffett M8 55.3?

Gradability and maneuverability determine whether a truck can reach rooftops, farms, or tight curbside locations without additional equipment. Loadmac emphasizes lower overall machine weight and balanced geometry, while four-way steering options improve lateral movement in confined spaces. Buyers comparing Moffett forklifts to Loadmac often notice the difference most on steep or uneven access roads.

How Loadmac 855 one-side offloading improves efficiency vs Moffett forklifts

One-side offloading uses a panograph extra reach that extends laterally from the truck so loads can be placed directly alongside structures or curbside without repositioning. This workflow contrasts with many Moffett truck mounted forklifts that require additional setup or stabilizer steps before handling heavy ground-level pallets.

- The panograph extra reach can reduce repositioning by multiple maneuvers per delivery.

- Lateral reach minimizes the need for ground workers to steady long loads.

- Unloading time is often shorter than rear-only methods common on Moffett truck mounted forklifts.

What is panograph extra reach and how does it work?

Panograph extra reach is a pantograph-style articulating system that pushes the forks outward while maintaining vertical stability. The linkage unfolds from a compact stowed position, allowing precise placement without moving the truck. By reducing repositioning and ground crew involvement, this system delivers faster and safer offloads compared to many traditional Moffett forklifts.

How does one-side offloading benefit lumberyards and construction sites?

One-side offloading reduces traffic obstruction, shortens per-delivery time, and minimizes idle truck movement. For lumberyards and construction sites, this means faster turnover and fewer lift-assist interruptions than workflows typically associated with Moffett truck mounted forklifts.

What safety features set the Loadmac 855 apart from Moffett truck mounted forklifts?

Safety depends on minimizing unnecessary operator movement, improving visibility, and simplifying service access. Loadmac emphasizes ground-level control concepts and clearer sightlines during lateral placement. When comparing Moffett forklifts to Loadmac, buyers should consider how many steps and stabilizer actions are required per lift cycle on Moffett truck mounted forklifts.

- Ground-level controls: Reduce climbing and fall risk during repeated cycles.

- Improved visibility: Enhances operator line-of-sight for lateral placements.

- Service access: Simplifies inspections and helps prevent undetected wear.

Last-Mile Delivery Optimization & Equipment Selection

Sustainable last-mile delivery is a key phase of modern logistics, with micro-hubs emerging to reduce repositioning and congestion in urban environments.

Micro-hub location selection for sustainable last-mile delivery, S Jovčić, 2022

Bottom line for buyers comparing Moffett forklifts

If your operation includes steep drives, tight jobsites, or frequent one-side drops, Loadmac’s workflow can eliminate steps and reduce repositioning. For fleets currently running Moffett forklifts or evaluating Moffett truck mounted forklifts, the real cost difference often shows up in time saved per delivery rather than on the spec sheet.

- Battle of Multidirectional Truck Mounted Forklift Giants: Loadmac 855 Super Reach 4-Way vs. Moffett M55.4P

- The Untold Secrets Behind a Piggyback Forklift That Really Works

- Loadmac 855 Super Reach: The Smarter Choice Over Moffett Forklifts and Princeton Piggyback Forklifts

- Unseen Truck Mounted Forklift Benefits for Your Business